Welcome Pragathi Cam Technology

Milling solutions

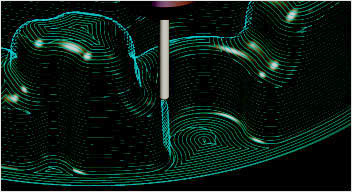

Mastercam brings its power and experience to artistic relief design and cutting with Mastercam Art. Now you can quickly bring your 2D sketches, clip art, photos, and CAD files to life by crafting them on screen and cutting them with easy, specialized toolpaths. Creating basic 2D art to sophisticated 3D sculpture in minutes, Mastercam Art is the ultimate tool for anyone trying to add that extra sculpted flair to their work.

Mastercam lets you go from "art to part" with a single software package. And, you don't need to be a surface modeling expert. A simple process takes you from your flat art to a beautifully sculpted piece that comes off the machine with exactly the look you want. Art has great visualization tools and instant editing features.

Key Features

- Create 3D sculpted models from 2D artwork.

- Create complex organic surfaces with a few simple clicks.

- Mastercam Art's various application styles let you add, subtract, intersect, and blend multiple organic shapes.

- Add textures, patterned surfaces, or wrap your art on a cylinder.

- Track your model step-by-step with Mastercam's Relief Manager, allowing quick and easy modifications any time you want.

- Using Mastercam's Solid Model Verification, you can see an on-screen simulation of your cut part before you put stock on the machine.

- Quickly create G-code for your machine using Mastercam's extensive post processor library.

One of the most complex 5-axis challenges is generating toolpaths for impellers, fans, and marine screws. These types of multi-bladed parts are used in many industries including power generation, energy transfer, and propulsion. Machining these complex shapes usually requires special multiaxis equipment, but Mastercam's Blade Expert is specifically designed to generate the necessary toolpaths for many of the different multi-blade configurations.

Blade Expert is a very powerful and easy-to-use custom application, designed to generate efficient, smooth, and gouge free toolpaths for these complex parts. It minimizes unnecessary motion at the machine, which results in a highly efficient toolpath with superior finish quality.

Multi-blade parts come in many configurations, but Blade Expert's common-sense operation process turns these machining challenges into routine solutions:

- Remove the material from between the blades

- Finish the blades/splitters

- Finish the floor

- Finish the fillets

The interface follows the already well-established Mastercam standard, used by all other multiaxis toolpaths, ensuring a short learning curve and successful deployment.

Key Features

- Precise, efficient, and smooth cut pattern.

- Automatic stock model awareness eliminates air-cuts.

- Automatic tool axis control ensures collision-free toolpaths.

- Accurate tool tip control means seamless blending and transformation.

Tool axis control is what separates multiaxis toolpaths from normal surface, chain, and point toolpaths. The ability to manipulate the angle of the tool, relative to the cut pattern, puts a greater amount of control in your hands. The cut speed, finish quality, and tool life can all be affected with tool axis control.

The power of multiaxis drill becomes apparent on parts that contain multiple holes with center lines pointing in different directions. Your multiaxis machine is capable of drilling many different holes with a single fixture setup, saving time and increasing productivity.

Curve/Drill 5-axis is the perfect entry into multiaxis machining, creating quality toolpaths while reducing programming time.

Key Features

- Curve 5-axis cuts a 3D chain or surface edges, generally for 5-axis trimming operations.

- Drill 5-axis simplifies the creation of 3-to 5-axis drilling output for holes in a part.

- Cost effective way to get into 5-axis machining.

- Generates 5-axis code that can run any CNC machine.

Mastercam Engrave brings the look of hand-carved art to mass produced parts. It brings a unique look of quality to a wide range of products — from signs to artwork to unique molds. Sharp inside corners give the finished piece a crisp edge and a "human touch".

Key Features

- Chisel and emboss images.

- Open pixel-based artwork as engrave geometry (.BMP, .GIF, .TIF, and more).

- Easily engrave any TrueType® font.

- Inverse embossing for mold work.

- Use V-groove cutters with any angle.

- Engrave remachining allows you to cut an area with a large tool and automatically remove remaining material with a smaller tool.

- Use constant-volume depth cuts for a more consistent tool load.

As a Mastercam customer, you know the value that top-of-the-line CAD/CAM delivers. Now you can enhance that value by making sure your Mastercam software is always up-to-the-minute – and your shop always has the latest tools to keep you ahead of the competition.

The Mastercam Maintenance Program is a software delivery plan designed to provide you with the most recent enhancements, the latest software tools, and the best new features. This means that your investment in Mastercam will continue to pay off by keeping your shop at the top of its game.

Maintenance Program allows you to budget your expenditures on an annual basis. Purchasing updates is no longer a budgetary variable. Now you can plan all your update costs in advance. New software is available to you immediately upon release, so you don't have to wait until your next budget is approved.

Key Features

- Major releases are made available to customers with active Maintenance at no additional charge.

- The software is marked for special handling to help ensure that Maintenance customers receive their software first.

- Maintenance customers have early access to any brand new features that are pre-released to Maintenance customers and you can download these as soon as they are ready.

- Special features on Mastercam.com are made available to maintenance customers only.

Mastercam Mill delivers fast, easy, industry-proven NC programming that lets you make the most of your machines. The Mill suite of CAD/CAM tools is focused on delivering speed and efficiency to your shop.

Since milling covers a huge range of disciplines—basic and complex 2D cutting to single-surface and advanced 3D milling—Mastercam offers an equally wide range of tools to make sure you can get your job done right. Mastercam also offers streamlined multiaxis cutting.

Ease of use, automation tools, live stock model, intelligent toolpaths, the ability to save your favorite cutting techniques, and much more all combine to deliver a fast, easy package that delivers the right tool exactly when you need it.

Key Features

- High Speed Machining combines high feed rates with high spindle speeds, specific tools, and specific tool motion, delivering faster turnaround and a superior finish.

- Dynamic milling delivers more consistent cutting, allowing use of the entire tool flute length while reducing machining time.

- High speed OptiRough removes large amounts of material faster and more efficiently than ever before.

- Hybrid finishing intelligently blends efficient cutting techniques into a single toolpath.

- 3D Toolpath Refinement allows unsurpassed control on surface cuts, delivering superior finishes and optimized cycle times.

- Rest milling (remachining) identifies and machines areas that need to be cut with a smaller tool.

- Feature Based Machining evaluates a part's features and automatically designs an effective machining strategy.

- Simulation gives you the confidence to run even the most complex cutter paths on your machine.Mastercam also offers streamlined multiaxis cutting for your 4- and 5-axis needs.

Multiaxis machining can dramatically increase a shop's competitiveness, and Mastercam's multiaxis add-on offers a wide range of multiaxis machining strategies—both basic and advanced. With Mastercam, you have complete control over the three crucial elements of multiaxis machining: toolpath types, tool motion, and tool axis.

Streamlined multiaxis programming tools make projects easier than ever before. With features from multisurface 5-axis roughing and swarf fanning, to easy 4-axis rotary axis and roll die programming, Mastercam ensures accurate cuts and fast turnaround on even the toughest jobs.

Key Features

- Multisurface 5-axis roughing and finishing, including depth cuts, plunge roughing, and flowline machining.

- Mastercam's advanced multiaxis machining lets you choose what type of project you are doing, and adjusts the interface to show exactly what you need.

- Axis limits control tool motion between defined angles, ensuring the tool tilt will not violate part or machine tool limits.

- Advanced gouge-checking and a 5-axis safe zone around the part help ensure safe cuts in even the most complex operations.

- Generates 5-axis code that can run any CNC machine.

- The Blade Expert add-on is specifically designed to generate the necessary toolpaths for many of the different multi-blade configurations.

- The Port Expert add-on creates accurate, efficient head porting toolpaths on port surface or solid data.

High yields can be crucial to a job's profitability. Mastercam includes essential nesting capabilities for parts and toolpaths that assure optimal material usage for the highest possible yields. With the capability to save sheet scrap for later use to the ability to create custom labels and reports, Mastercam's Nesting function can help keep your shop running efficiently.

Mastercam's standard nesting delivers a fast, efficient, and easily identifiable way of nesting your parts. Mastercam's advanced nesting gives a variety of additional tools, including TrueShape nesting and nesting in scrap material.

Key Features

- Fast, efficient interlocking part nesting maximizes material use.

- Complete control over part-to-part distance, sheet margins, and more.

- Easily "drag" parts around on your sheet.

- Directly place CAD models from a variety of sources.

- Group sets of parts and assign part nesting priorities.

- Double-sided and common-edge nesting.

- Custom sheet definition and "filler" parts reduce waste.

- Automatic vertical/horizontal cut-offs preserve rectangular leftovers.

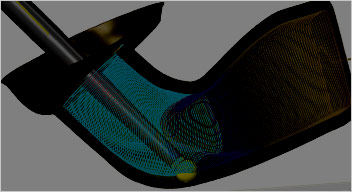

Mastercam's Port Expert add-on creates accurate, efficient engine cylinder head porting toolpaths on port surface or solid data. It minimizes unnecessary motion at the machine, which results in a highly efficient toolpath with superior finish quality. It can also be used for any tube type work that is similar in design to a port. Port Expert uses a tapered lollipop tool, and has collision checks for the entire tool (shank, arbor, and holder).

There are multiple cutting options available with Port Expert. For instance, you can cut only the top; cut only the bottom; or specify how much stock to leave on the entire port.

The Port Expert toolpaths use 3-axis machining as far into the port as possible, and then convert automatically to 5-axis motion with minimum tilt. This leaves no fishtails or inefficient reverse moves, and smoothly transitions where the toolpaths meet at the middle of the port.

Key Features

- Port Expert provides both roughing and finishing toolpaths to make ports from castings or billets.

- Geometry can be made of multiple surfaces that are stitched together since Port Expert supports unlimited surfaces.

- Automatically calculates optimal tilt angles so there is no need to split the surface or create tool axis control splines.

- Mastercam's simulation proceeds step-by-step through the toolpath, even showing the motion used in transition at the middle of the port.

- Generates 5-axis code that can run any CNC machine.

- Simplifies the programming of complex port shapes.

- Greatly decrease programming time.